Wash Heating

When quoting or specifying a wash system (whether it be a cubicle or conveyed tunnel washer), heating capacity can be an important factor. Too little and the machine will not attain the required temperatures, too much and the system can be wasteful – or result in the heating system dropping in and out too frequently.

There are several areas within a machine that need to be considered in order to ensure the equipment has enough heating to overcome the system losses. Firstly, the type and number of items to be washed per hour within the machine affects the amount of heat that is transferred to the products as they are subjected to the heated water.

For instance if a machine is to handle both plastic and stainless steel trays racks etc, then care has to be taken with the calculations, as the different materials will take differing amounts of heat energy from the liquid due to their relative specific heat capacities. So if the machine was achieving temperature, at maximum capacity, on steel trays for arguments sake, then it would struggle with plastics at the same given throughput weight.

Water flow and jet design are also contributing factors. On a re-circulated system, temperature is lost as soon as the water emerges from the jet, and the rate of heat loss is proportionate to the flow of the pump and jetting system. This however can also be controlled if the design of the jet and the pressure of the water is considered. The aim is to keep the water flow as full as possible, minimizing atomization at the jet tip, as this atomization will increase the surface area of water exposed to the air, resulting in a greater heat loss. Correct jet system design will minimize this without compromising the required wash pressure. Jetting system design will be discussed in a later talk.

Heat transfer to the steel surfaces of the machine can also be reduced by minimizing the time that the water has to return to the reservoir, so if the jetting can take place virtually above the reservoir, the heat transfer to the return trays (the sloping surface on which the water runs back to the tank) can be lower. If not, then this heat transfer must be allowed for in the system design but is quite often overlooked.

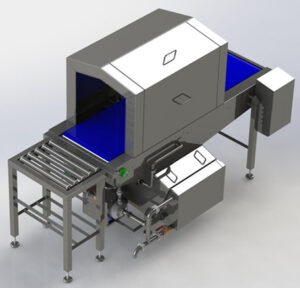

Extraction fans can also be a cause of undue and unexpected heat loss within a machine. The positioning of the fans can have a big impact of heat removal from the system. Extraction fans, on a tunnel type machine, should be positioned at the ends of the tunnel. This allows the fans to draw in fresh air from outside of the tunnel, creating a barrier for the hot water vapour, rather than drawing heat and excessive water from within the unit. Often it has been seen where extraction fans have been positioned at the centre of the machine, drawing vapour from directly above the tanks, with the argument that they only use a single fan. The false economy of this is that you are pulling excessive heat from the working area, and also inducing a cool air flow along the machine, again increasing the heat loss. In a cubicle unit there is no easy way around this, as the fan has to be within the work area, but programming when and how often the fan operates, can minimize the effects.

Heating systems should be designed so that there is little waste or excessive heat. There are several methods of recovering some of the heat lost in flues, and flash steam and condensate recovery in steam coil heating is generally used industry wide. In gas heated systems this can be difficult, as the dew point needs to be exceeded therefore there is a minimum temperature at which the gasses should leave the machine. Some manufacturers will claim that they use excess heat from a gas flue to heat other areas of the unit, for instance air knives. However if the system is designed correctly there should be no waste heat. Any extra energy that is taken from the gas heating system downstream of the tank coil has to be over and above that which the tanks need, to ensure the gasses are above the dew point temperature. So this is not free heat it is additional heat required. Often it is thought that if the machines are fed with heated water, then the heating systems within the machines can be reduced considerably. The answer to this is yes they can be reduced, but only slightly. Normally a machine can be filled with hot water and reduce the warm up time, but when running, the flow of water from mains should be minimized to reduce utility usage. The only flow should be top up water for that which is carried out of the system on the products, and possibly a rinse clarification flow (to dilute detergent residue from carry over), if the machine has a re-circulated final rinse. The heat energy in this minimal running flow is far outweighed by the heat losses to the jets and products, which is the largest heat losses in the system, so when running, the reduction in heat energy required, by providing hot top up water is small, possibly as low as 1-2% of the total usage.

Heating issues, or problems in maintaining liquid temperatures are ones that users can experience far too often, and the fact is when you have spent considerable funds on a machine that doesn’t quite get there, do you remove it from site and replace it with a capable unit? Very often not. The most you may expect is a cost reduction from the manufacturer, which in the long term will not overcome the compromises you may have to make.

Effective Sanitizing

Effective Sanitizing