Streamlining Large Kitchen Operation Hygiene with Tunnel Washers

In busy commercial kitchens, maintaining the strictest standards for hygiene is not just a priority—it’s a necessity. Whether it’s a restaurant, a cafeteria, or a high-volume catering service, cleanliness is essential to ensure food safety, uphold health regulatory standards, and preserve the reputation of the establishment. In these demanding environments, where dishes pile up quickly and operations move at a fast pace, traditional manual dishwashing methods often fall short. This is where tunnel washers can be a game-changer, revolutionizing large-scale kitchen hygiene management.

The Popularity of Tunnel Washers

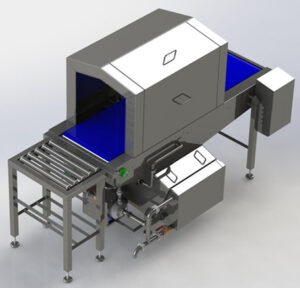

Tunnel washers, also known as conveyor dishwashers, represent a huge stride forward in kitchen hygiene technology. Unlike traditional manual dishwashing methods, which are labor-intensive and time-consuming, tunnel washers automate the process, offering effective cleaning, efficiency, and consistency on a large scale.

How Tunnel Washers Work

Tunnel washers use a conveyor belt system that transports soiled dishes through a series of cleaning stages. These stages typically include pre-washing, washing, rinsing, sanitizing, and drying. Each stage is carefully calibrated to ensure optimal cleaning performance while minimizing water and chemical usage. Advanced models may also feature sensors and programmable settings to adapt to varying levels of soiling and adjust accordingly.

Advantages of Tunnel Washers

Efficiency – Depending on the system, tunnel washers can process anywhere from 100 to 6,000 units per hour, significantly reducing turnaround time to keep up with high-demand situations. This efficiency translates to increased productivity and smoother operations in large kitchen environments.

Consistency – Tunnel washers remove the uncertainty of human error and inconsistency in the cleaning process. Automation ensures that each unit undergoes precisely the same thorough cleansing regimen, eliminating the risk of oversight and ensuring consistently high hygiene standards.

Resource Optimization – By precisely controlling water, detergent, and energy usage, tunnel washers help kitchens optimize their resource consumption. This not only reduces operational costs but also minimizes environmental impact.

Enhanced Hygiene – The multi-stage cleaning process of tunnel washers provides thorough elimination of contaminants, ensuring that dishes are sanitized and safe for use. This level of hygiene is crucial for meeting regulatory standards and safeguarding the health of customers and staff alike.

Labor Savings – By automating the dishwashing process, tunnel washers significantly reduce the need for manual labor in the kitchen. This frees up staff to focus on other essential tasks, such as food preparation and customer service for overall improved efficiency and quality of service.

Unitech Tunnel Washers Benefits for Large Kitchen Operations

Designed to optimize hygiene in commercial environments, Unitech tunnel washers feature sloping surfaces to help reduce the downtime needed for routine cleaning and maintenance. Other advantages include:

- Design that allows for continuous in-line washing for crates and trays

- Effective cleaning via stainless steel, quick release 360° jetting

- Multiple pre-wash, wash, rinse, sanitizing and drying options available

Please contact us to learn more about tunnel washers from Unitech Washing Systems.

Effective Sanitizing

Effective Sanitizing